AquaMatic 962 stager control provides an easily adaptable control of stagers for diaphragm valve nests. This fully programmable series of controls provide the ability to fine tune the operation to meet application requirements.

This product is manufactured in the United States of foreign and domestic parts.

|

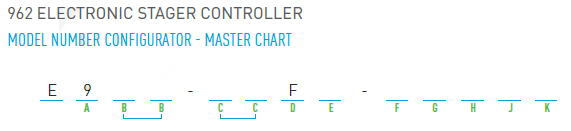

A. Controller

B. Stager

C. Program

D. Enclosure

E. Electrical

|

F. 1st Aux. Switch

G. 2nd Aux. Switch

H. Pressure

J. Relay Output Option

K. Stager Revision

|

Proudly made in the USA

from foreign & domestic parts.

AqMatic is now the company producing AquaMatic valves and will, over time be re-branding them as AqMatic valves.

AquaMatic is still the same quality product line that you have come to know and love.

2827 Midway Rd SE

Suite 106, Box #107

Bolivia, NC 28422

Tel: 980.458.2583

Cell: 336.462.1926

Fax: 336.595.9555

sales@buyaq-matic.com