In any high-demand industrial system, diaphragm valves are critical components that regulate flow and protect against contamination or backflow. However, like any part exposed to pressure, corrosive media, or repeated cycles, diaphragm valves can fail—often without obvious external signs.

Recognizing the early indicators of industrial valve failure helps avoid costly system downtime:

– Inconsistent or reduced flow rate

– Unusual hissing or leaking sounds

– Valve not fully opening or closing

– Frequent alarms or irregular pressure spikes

Routine maintenance should include these checks to ensure you catch problems early. If your diaphragm valve shows any of these signs, it’s time to inspect and potentially replace it.

Rebuilding a diaphragm valve is a manageable process for most maintenance teams.

1. Isolate and depressurize the system

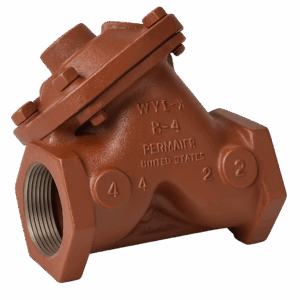

2. Identify the valve model and series

3. Disassemble the valve carefully

4. Inspect the diaphragm and internal seals

5. Rebuild with new AQ Matic parts

6. Pressure test the system

When it’s time to replace your valve or rebuild it with new parts, AQ Matic provides a wide range of diaphragm assemblies and seal kits tailored to their valve series.

Popular kits include:

– Diaphragm & Seal Kits (rubber components)

– Internal Parts Kits (metal components)

Take a look at the tables below to identify the repair kits needed for your AQ Matic valves. Using genuine AQ Matic parts ensures compatibility and extends the service life of your system.

Note: Letters in column A only apply to metal valves

Note: 53 valves are only available in Normally Open with the exception XNC

Note: Click on a table image below to download file with links to product pages OR type the 107 part number in the search bar at the top of the page

A successful diaphragm valve replacement doesn’t end after reassembly. Ongoing maintenance is key to protecting your system’s performance.

Maintenance tips:

– Log valve maintenance and replacements

– Inspect diaphragm valves quarterly

– Keep a stock of emergency kits

– Train your maintenance staff using diagrams and videos

If you’re unsure which diaphragm valve or repair kit you need, our experts at Buy-AQ-Matic.com can help. We’re an AQ Matic distributor and offer fast shipping and technical support. Browse our full Repair Kit options or contact our support team at Sales@BuyAQ-Matic.com or call 980-458-2583 for a quote or compatibility check.

Faulty diaphragm valves can quietly cripple your system—unless you know what to look for and how to fix them. With the right inspection approach and certified AQ Matic repair kits, your facility can minimize downtime and keep operations running smoothly.

Looking for more industrial valve tips? Explore our full Valve Repair and Maintenance Hub for guides, part identification help, and downloads.